The true key to slashing your heating bills isn’t the R-value printed on insulation, but eliminating the hidden energy leaks in your home’s structure.

- Wood framing’s “thermal bridges” (the studs themselves) can sabotage your insulation’s performance, creating cold spots and wasting energy.

- Insulated Concrete Forms (ICF) create a continuous, airtight envelope that dramatically outperforms traditional walls in real-world Canadian conditions.

Recommendation: Shift your focus from comparing individual material R-values to evaluating the performance of the entire building envelope as a single, integrated system.

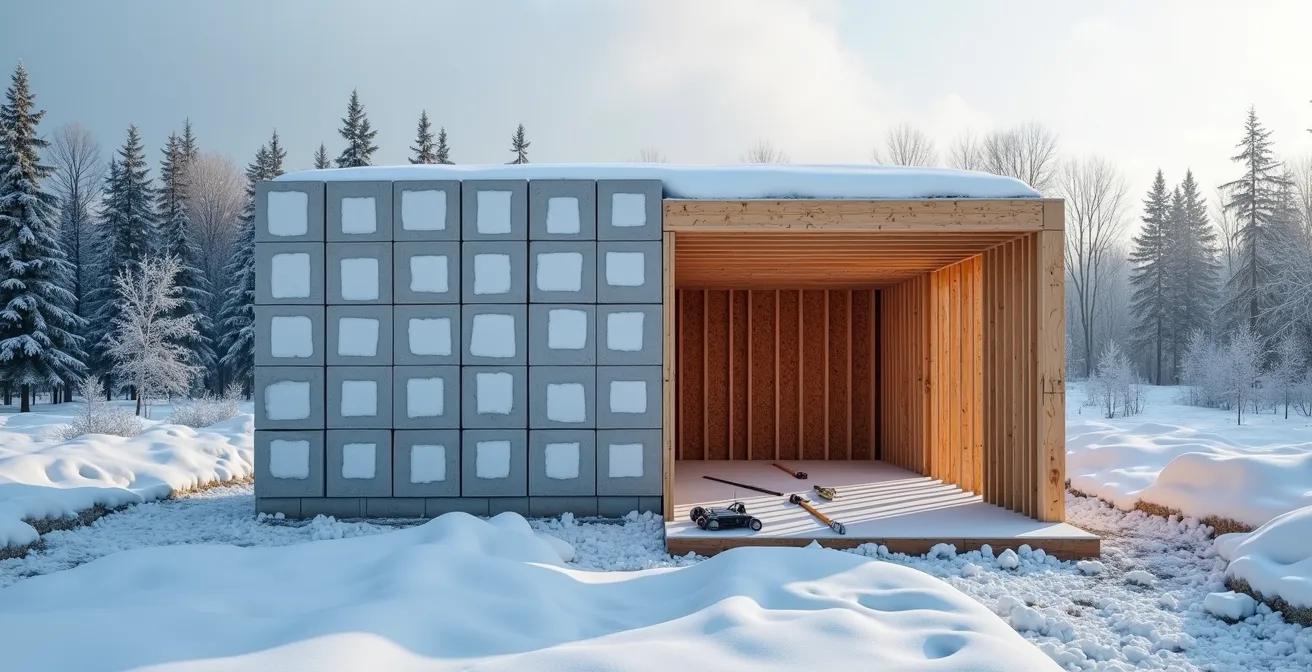

As a self-builder in Canada, you’re not just constructing a house; you’re making a decades-long financial and lifestyle investment. The choice of structural system—the bones of your home—is the most critical decision you’ll make. For generations, the default answer has been wood framing. It’s familiar, fast, and every contractor knows it. The conventional wisdom says to pack those stud cavities with the highest R-value insulation you can afford and call it a day.

But what if that entire approach is flawed? What if the very studs that hold up your walls are also creating thermal “superhighways” for your expensive heated air to escape into the cold Canadian winter? This is the reality of thermal bridging. The discussion often gets bogged down in comparing R-values, but this misses the bigger picture. We’re led to believe that a higher number automatically means a warmer, more efficient home. It’s time to look beyond that myth.

The real question isn’t about what’s *inside* the wall cavity; it’s about the performance of the wall as a complete, uninterrupted system. This is where Insulated Concrete Forms (ICF) change the game entirely. Instead of focusing on fighting energy loss through a series of joints and studs, an ICF structure is designed from the ground up to prevent it. It’s a fundamental shift from a collection of parts to a holistic, high-performance envelope.

This guide will walk you through the practical, real-world implications of this choice, from preventing mould in your basement to calculating the actual payback period on your investment. We’ll move beyond theoretical numbers and look at how these systems perform where it matters most: in your home, through a Canadian winter.

For those who prefer a condensed overview, the following video offers a great comparison of the pros and cons of ICF, SIPs, and traditional framing systems.

To help you make an informed decision, we’ve broken down the key considerations a self-builder faces. This article examines the tangible impacts of choosing ICF over traditional wood framing, from your foundation to your finishing touches, all within the specific context of the Canadian climate and building landscape.

Summary: The Homebuilder’s Guide to ICF vs. Wood Frame in Canada

- Spray Foam or Rigid Board: What Prevents Mold in a Wet Basement?

- Why Bamboo Flooring Might Warp in Canada’s Dry Winter Climate?

- The R-Value Myth: Why Higher Numbers Don’t Always Mean Warmer Rooms?

- Where to Find Reclaimed Barn Wood in Ontario Without Paying Boutique Prices?

- When Will Your $10,000 Insulation Upgrade Finally Pay for Itself?

- Stucco vs. Cedar: Which Siding Rots Faster in Coastal BC Humidity?

- The Greener Homes Grant Mistake That Delays Reimbursement by 6 Months

- Why Triple-Glazed Windows Are Mandatory for Lowering Heating Bills by 30%?

Spray Foam or Rigid Board: What Prevents Mold in a Wet Basement?

The battle for a dry, healthy basement begins with the walls. A common approach for wood-framed basements is to build a 2×6 wall inside the concrete foundation, then fill the cavities with spray foam or rigid board. The problem is, this creates multiple layers and seams where moisture can get trapped. Every wood stud is a direct path for cold from the foundation to travel into the wall assembly, creating a thermal bridge. When warm, moist indoor air hits these cold spots, it condenses—creating the perfect breeding ground for mould inside your walls.

ICF construction eliminates this fundamental flaw. The structure *is* the insulation. You have a solid, monolithic concrete core sandwiched between two continuous layers of high-density foam insulation, from the footing right up to the rafters. There are no studs, no cavities, and therefore no thermal bridges to create condensation points. This continuous insulation keeps the concrete core at a stable temperature, well above the dew point, effectively eliminating the risk of condensation and mould growth from within the wall assembly itself.

The performance difference is not trivial. Independent testing confirms the superiority of this system. A case study conducted by CLEB Laboratories in Canada compared an ICF wall to a standard insulated wood frame wall. The results were stark: the ICF assembly provided superior moisture control by completely eliminating the thermal bridging that plagues stick-built basements. This structural integrity translates directly into a healthier living space, as the continuous barrier is far less permeable to moisture infiltration from the surrounding soil.

In fact, testing commissioned by the ICF Manufacturers Association shows an ICF wall can have a 58% better effective R-value than a traditional 2×6 wood frame wall, largely because it stops the air leaks and thermal bridging that are not accounted for in a simple component R-value rating.

Ultimately, choosing ICF for your foundation isn’t just an insulation upgrade; it’s a proactive strategy to build a mould-resistant, structurally superior, and healthier basement from day one.

Why Bamboo Flooring Might Warp in Canada’s Dry Winter Climate?

ICF walls offer all the strengths we could possibly need

– Up To Kode Carpentry, Canadian ICF builder testimonial

You’ve chosen beautiful bamboo or hardwood flooring for your new home. But in the dead of a Canadian winter, the furnace is running constantly, and the indoor air becomes incredibly dry. In a typical wood-framed house, this dryness is compounded by poor airtightness. The house “breathes” excessively, leading to significant swings in indoor humidity. Natural materials like wood flooring expand and contract with these changes, leading to gapping, cupping, or even warping over time. It’s a frustrating problem that many homeowners mistake for a flooring defect when it’s actually a building envelope failure.

This is where the superior airtightness of an ICF home provides a crucial, often overlooked, benefit. Because an ICF structure is a monolithic system with far fewer joints and seams, it is inherently more airtight than a wood-framed house. This dramatically reduces uncontrolled air leakage, allowing a Heat Recovery Ventilator (HRV) or Energy Recovery Ventilator (ERV) to manage the indoor environment precisely. The result is a much more stable indoor humidity level, typically maintained between 35-45% year-round.

For your expensive interior finishes, this stability is everything. It means your wood floors, custom cabinetry, and drywall remain in the controlled climate they were designed for, minimizing seasonal movement and preserving their integrity and appearance for decades. The investment in an ICF shell acts as an insurance policy for every finish you put inside it.

The data below illustrates the stark difference in environmental stability between the two construction types. A typical wood-frame home can have 3 to 5 air changes per hour (ACH), while a well-built ICF home is often in the range of 0.5 to 1.5 ACH, creating a calm, stable interior climate.

| Building Type | Air Changes per Hour | Humidity Control | Temperature Stability |

|---|---|---|---|

| ICF Construction | 0.5-1.5 ACH | Stable 35-45% with HRV | ±1°C variation |

| Traditional Wood Frame | 3-5 ACH | Fluctuates 20-60% | ±3-5°C variation |

By choosing a structure that provides a stable foundation, you aren’t just building an efficient home; you’re creating a protective environment for all the beautiful materials within it.

The R-Value Myth: Why Higher Numbers Don’t Always Mean Warmer Rooms?

The term “R-value” is the most common metric used to sell insulation, and the logic seems simple: bigger is better. A wall assembly with R-24 insulation must be better than one with R-22. This is the R-value myth. This number only measures the thermal resistance of the insulation itself, in a perfect laboratory setting. It completely ignores the single biggest source of heat loss in a wood-framed wall: the wood studs themselves. A wood stud has an R-value of only about R-6. In a standard wall, up to 25% of the surface area is wood, not insulation. These studs act as thermal bridges, creating a network of cold pathways for heat to escape your home.

This is why engineers and building scientists refer to “effective R-value.” This metric considers the performance of the entire wall assembly, including the thermal bridging of the studs and any air leakage. When you measure the effective R-value, a “R-22” wood-framed wall might only perform at an R-16 in real-world conditions. You’re paying for performance you simply aren’t getting.

ICF construction shatters this paradigm. Because there are no studs, there is no thermal bridging. The insulation is continuous, wrapping the entire structure in an unbroken blanket. The stated R-value of an ICF block (typically R-23 or higher) is much closer to its “effective R-value” because the system has no inherent weak points. Add to this the thermal mass of the concrete core, which absorbs and releases heat slowly, and the superior airtightness, and the performance gap widens dramatically.

This isn’t just theory; it’s proven by real-world data. Numerous studies demonstrate that ICF exterior walls require up to 44% less energy to heat than their wood-framed counterparts. This massive saving doesn’t come from a slightly higher R-value number on the insulation; it comes from a smarter system that actually delivers the performance it promises.

When you choose your building system, don’t be fooled by a single number. Look at the whole system and ask which one eliminates the weak points where your energy dollars are actually lost.

Where to Find Reclaimed Barn Wood in Ontario Without Paying Boutique Prices?

Choosing a high-performance ICF structure doesn’t mean you have to sacrifice aesthetics. Many self-builders love the warm, rustic look of wood but want the unmatched energy efficiency and durability of a concrete core. Reclaimed barn wood is a fantastic way to get that classic look for feature walls or exterior accents. The challenge in a province like Ontario is that “reclaimed wood” has become a boutique product with a high price tag. However, with a little strategy, you can source it directly for a fraction of the cost.

The key is to get ahead of the supply chain. Instead of buying from a reseller, you want to connect with the source: farmers and demolition contractors. As agricultural practices change, many older “century barns” are being taken down. This is your opportunity. The weathering and patina on these old boards are impossible to replicate and tell a story of the local landscape.

Finding these opportunities requires a bit of legwork, but the payoff is substantial. By focusing your search on rural areas undergoing change and building relationships with the right people, you can secure beautiful, historic material that adds immense character to your modern, efficient home.

Your Action Plan: Sourcing Affordable Barn Wood in Ontario

- Target rural counties: Focus searches and drives in regions like Huron, Perth, and Grey-Bruce where farm consolidation is common and older barns are more prevalent.

- Master Kijiji searches: Use specific, non-commercial search terms like “barn demolition,” “farm teardown,” or “century barn” combined with specific township names.

- Contact demolition contractors: Proactively reach out to demolition companies that specialize in agricultural buildings. Let them know what you’re looking for so they can call you when a suitable project comes up.

- Monitor municipal demolition permits: Check the websites of rural townships. They often post upcoming demolition permits, giving you a heads-up on potential salvage opportunities.

- Join Ontario barn preservation groups on Facebook: These online communities are filled with enthusiasts and professionals who often share salvage opportunities before they are publicly listed.

Pairing the historic character of reclaimed wood with the cutting-edge performance of an ICF shell gives you the best of both worlds: timeless style and future-proof efficiency.

When Will Your $10,000 Insulation Upgrade Finally Pay for Itself?

The most common hesitation self-builders have about ICF is the upfront cost, which can be 3-5% higher than a standard wood-framed house. Let’s translate that: on a $300,000 build, that might be an extra $9,000 to $15,000. So, the critical question is: is it a cost or an investment? The answer lies in the payback period—the time it takes for your monthly energy savings to completely cover that initial premium. And in Canada, that payback is often much faster than you think.

Unlike a cosmetic upgrade, the superior performance of an ICF building envelope starts paying you back from the very first heating bill. With heating and cooling savings often reaching 40-50% per month, the return on investment becomes a simple calculation. The exact payback period, however, depends heavily on one key factor: your local energy costs. Provinces with higher electricity or heating oil prices will see a much quicker return.

A builder in Nova Scotia, facing high oil and electricity costs, could see their investment pay for itself in under six years. In Ontario or Alberta, where natural gas is more prevalent, the payback period might be slightly longer but is still well within a decade. This calculation transforms the “extra cost” of ICF into a predictable, high-return investment that also delivers superior comfort and durability.

The table below provides a simplified look at potential payback periods based on an estimated $10,000 ICF premium and typical energy savings in different Canadian provinces. Your actual savings will vary, but this illustrates how local energy prices dramatically affect the ROI.

| Province | Energy Source | Annual Savings | Payback Years |

|---|---|---|---|

| Quebec | Hydro | $800 | 12.5 |

| Ontario | Natural Gas | $1,400 | 7.1 |

| Alberta | Natural Gas | $1,200 | 8.3 |

| Nova Scotia | Oil/Electric | $1,800 | 5.6 |

When you factor in the long-term energy savings and the eligibility for programs like the Canada Greener Homes Grant, the financial case for ICF becomes not just viable, but compelling. It’s an investment in permanently lower carrying costs for your home.

Stucco vs. Cedar: Which Siding Rots Faster in Coastal BC Humidity?

In the relentless damp of coastal British Columbia, moisture is the enemy. For wood-framed buildings, the “leaky condo crisis” of the 90s served as a harsh lesson in moisture management. This led to the mandating of rainscreen systems, which create an air gap behind the siding to allow moisture to drain and dry. However, a rainscreen is only as good as the wall system behind it. If moisture finds its way past the building paper and into a wood-stud wall, it can get trapped in the insulation, leading to rot, mould, and structural failure from the inside out.

This is a scenario where an ICF system offers profoundly superior resilience. An ICF wall’s solid, non-organic concrete core is monolithic and waterproof. It acts as a built-in, robust vapour and air barrier. When properly paired with a rainscreen siding system (whether it’s stucco, cedar, or composite panels), you create a two-stage defence. The rainscreen manages the bulk of the rainwater, and the ICF core provides an impermeable backstop, ensuring that any incidental moisture that gets through has nowhere to go but down and out. There are no cavities to flood or organic materials to rot.

The practical application of this in BC’s climate is significant. A properly executed ICF project in a high-humidity environment like the Lower Mainland is simply more durable. Local experience backs this up.

Case Study: Coastal BC Moisture Management with ICF

In coastal BC’s rainscreen-mandatory construction, ICF walls paired with proper exterior cladding systems demonstrate superior moisture management. The monolithic concrete core acts as a powerful barrier, preventing the deep moisture infiltration that commonly affects wood-framed structures in the region. According to a review of local installations by Vancouver ICF, their projects show zero moisture-related failures when proper drainage planes are maintained, a stark contrast to the frequent callbacks for wood-frame assemblies experiencing issues in the Lower Mainland’s notoriously wet climate.

Of course, proper installation is critical. Adhering to the BC Building Code for rainscreen application is non-negotiable for any wall system.

Checklist: BC Building Code Compliance for ICF Siding

- Install rainscreen gap: Ensure a minimum 10mm (3/8″) air gap is maintained behind the cladding as per BC Building Code 9.27.2.

- Use corrosion-resistant fasteners: All screws and attachments must be rated for coastal exposure, such as Type 316 stainless steel, to prevent premature failure.

- Include insect screening: The top and bottom of the rainscreen cavity must be protected with screening to prevent pests from nesting.

- Install a moisture-resistant barrier: A proper weather-resistant barrier must be applied over the ICF foam surface before attaching furring strips or cladding.

- Ensure a continuous drainage path: Use drainage mats or properly oriented furring strips to guarantee that water can drain freely down and out of the wall assembly.

In a high-risk environment, choosing a system with inherent resilience to moisture isn’t just a good idea—it’s essential for the long-term health and durability of your home.

The Greener Homes Grant Mistake That Delays Reimbursement by 6 Months

The grant is not for ICF itself, but for the home’s overall performance

– Natural Resources Canada, Canada Greener Homes Initiative Guidelines

The Canada Greener Homes Grant is a powerful tool for self-builders, offering significant rebates for constructing a high-performance home. However, many people misunderstand how it applies to an ICF build. As Natural Resources Canada clarifies, you don’t get money simply for *using* ICF. You get reimbursed based on the final, tested energy performance of your entire home as a system. This is great news for ICF builders, as these homes test exceptionally well, but it also creates a major administrative pitfall: process matters. One simple mistake in the sequence of events can delay your reimbursement by six months or more.

The single most common and costly error is starting work before the pre-retrofit evaluation is complete. The program is designed to measure the *improvement* over a baseline, and for a new build, that baseline must be established by an energy advisor based on your plans *before* you even break ground. Scheduling your advisor to come out after the foundation is poured is too late and can lead to major headaches with your application.

Navigating the grant successfully requires meticulous documentation and proactive communication with your energy advisor. They need the exact specifications of your chosen ICF system, the performance data of your windows and HRV, and they must be notified of any changes to the plan along the way. Think of the grant process not as a simple rebate form, but as a detailed audit of your project. Keeping your paperwork in perfect order is the key to a smooth and timely reimbursement.

Action Plan: Avoid Critical Greener Homes Grant Delays

- Schedule pre-retrofit evaluation first: Your first call should be to an energy advisor. Do NOT begin any site work, including excavation or foundation, until this evaluation is officially logged.

- Vet your energy advisor: Ask potential advisors if they have experience modelling ICF homes. An advisor unfamiliar with ICF may use incorrect assumptions, hurting your final rating.

- Document ICF specifications: Provide your advisor with the manufacturer’s certification, exact foam thickness, and system R-value for their energy model.

- Keep all ENERGY STAR receipts: Maintain a perfect record of receipts for all major components, especially windows, doors, heat pumps, and your HRV/ERV system.

- Submit change requests immediately: If you decide to upgrade your windows or change the ICF block thickness midway through, inform your advisor and have them update the model *before* installation.

- Complete the blower door test promptly: Schedule your post-build evaluation and mandatory blower door test as soon as the house is substantially complete to finalize your file.

By treating the grant process with the same diligence as your construction, you can ensure your high-performance home is rewarded as it deserves.

Key Takeaways

- Real-world energy performance is determined by the entire building system, not just the R-value of insulation.

- Thermal bridging in wood-framed walls is a major, often-ignored source of heat loss that ICF construction eliminates.

- The superior airtightness of ICF creates a more stable and healthy indoor environment, protecting interior finishes and improving comfort.

Why Triple-Glazed Windows Are Mandatory for Lowering Heating Bills by 30%?

Building an ultra-efficient ICF wall system and then installing cheap, low-performance windows is like buying a race car and putting on bicycle tires. You’ve created a nearly impenetrable thermal fortress, but you’ve left the gates wide open. In a modern, high-performance home, the windows are often the weakest link in the building envelope. As you dramatically improve the performance of your walls with ICF, the proportion of total heat loss that occurs through your windows increases significantly. To truly reap the rewards of your ICF investment, upgrading to high-performance, triple-glazed windows isn’t just a good idea—it’s mandatory.

Triple-glazed windows, with their multiple panes, low-E coatings, and argon or krypton gas fills, offer a U-factor (a measure of heat loss) that is substantially lower than standard double-glazed units. This performance is critical to matching the efficiency of your ICF walls. When you pair a super-insulated, airtight wall system with high-performance glazing, you complete the building envelope. The two systems work in synergy, minimizing both conductive heat loss and air leakage across the entire structure.

The impact of this pairing is profound. While an ICF structure alone can cut heating energy needs by up to 44%, the total savings climb even higher when the window performance is brought up to the same standard. According to some building science research, ICFs can reduce energy consumption by up to 60% when combined with other energy-saving features like high-performance windows. This is how you get to the dramatic reductions in heating bills that make the upfront investment in a better building system pay off so quickly.

For any Canadian self-builder serious about minimizing long-term energy costs, the decision is clear: an ICF structure paired with triple-glazed windows isn’t an extravagance; it’s the foundational strategy for creating a truly efficient and comfortable home for the future.